WE WELCOME OUR NEW SITE SPONSOR CAPITAL ONE!

![]() CLICK HERE TO DONATE TO HELP FUND THIS SITE!

CLICK HERE TO DONATE TO HELP FUND THIS SITE!

NEW CLICK HERE TO SEND US A GIFT! A COOL IDEA TO HELP US FOR HELPING YOU!

NEW CLICK HERE FOR THE AMAZON PRIME PAGES!

NEW CLICK HERE FOR HOLIDAY CARDS AND WRAPPING PAGES

NEW CLICK HERE FOR THE UPS PAGES

NEW CLICK HERE FOR THE 2000 4.1 TOYOTA RAV4 PAGES

NEW CLICK HERE FOR HOME AUTOMATION PAGES ALEXA AND FIRE TV AND GOOGLE HOME ITEMS

NEW CLICK HERE FOR Y 3 K PAGES

NEW CLICK HERE FOR THE HOUR METER PAGE

CLICK HERE FOR THE FITTINGS ID PAGES FOR HOSES AND PORTS

NEW CLICK HERE FOR HYD ORINGS PAGES

CLICK HERE FOR THE BIG SHOP TOOLS PAGES

CLICK HERE FOR THE LISLE TOOLS PAGE

CLICK HERE FOR THE THREAD SIZE PAGE

CLICK HERE FOR THE BOLT TORQUE PAGE

CLICK HERE FOR CONSTRUCTION PAGES

CLICK HERE FOR THE WIND POWER PAGES

CLICK HERE FOR HEALTH CARE PAGES

CLICK HERE FOR TV ANTENNA AND ROTOR PAGES

CLICK HERE FOR THE ELECTRONICS PAGES

CLICK HERE FOR THE SAFETY PAGES

NEW CLICK HERE FOR LOCKS PAGES

CLICK HERE FOR IPAD IPHONE PAGES

CLICK HERE FOR THE TRACK AND TELL PAGES

CLICK HERE FOR WORK CLOTHING PAGES

CLICK HERE FOR THE LITHIUM RECHARGEABLE BATTERY PAGES

CLICK HERE FOR THE EMERGENCY LIGHTS PAGES

CLICK HERE FOR THE BELT ALIGNMENT PAGES

CLICK HERE FOR THE HVAC AIR CONDITIONER PAGES

NEW CLICK HERE FOR THE HOT WATER HEATER PAGES WITH RECIRCULATION PUMPS

CLICK HERE FOR THE WINDOW TINT PAGE WITH BLACK OUT TINT TOO!

CLICK HERE FOR THE CAMPER TRAILER LIGHTS WIRING DIAGRAM PAGE

CLICK HERE FOR THE TRAILER TOW PAGES

NEW CLICK HERE FOR THE DIESEL REPAIR PAGES

IECO 210 HP 4 CYL / POUSTUSA CHEVY VEGA PAGE

RADIO SERVICE RADIO CONVERSION AND MORE

SALVAGE YARD LINKS STATE BY STATE LISTINGS

CLICK HERE FOR EQUIPMENT AND SMALL ENGINE PAGES WITH LINKS HONDA PAGES TOO AND HOW TO!!

CLICK HERE FOR THE MOUSE TRAP PAGES A TRAP THAT WORKS FOR US!!

CLICK BELOW FOR THE COOL UNIT CONVERTER SITE

CLICK HERE FOR SHOP TOOLS AND EQUIPMENT PAGES

CLICK HERE FOR MUST HAVE TOOLS LIST PAGE

CLICK HERE FOR AIRCON SOFT START PAGES

CLICK HERE FOR THE INVERTER WINDOW AC UNITS

CLICK HERE FOR THE ELECTRICAL TOOLS AND PARTS PAGES AND MORE!

NEW CLICK HERE FOR RESTAURANT PAGES

NEW CLICK HERE FOR TRUCK CRAIN BED LIFTS

NEW AUXITO ULTRA BRIGHT LED LIGHTS

NEW SEAT BELTS FOR YOUR HOTROD AND MORE

CLICK HERE FOR THE POWER WASHER PAGES

CLICK HERE FOR THE DRAINZIT OIL DRAIN PAGES

CLICK HERE FOR THE DC FUSE PAGE ATO, ATC, MAXI, GMA

NEW CLICK HERE FOR THE SURVIVAL PAGES

NEW CLICK HERE FOR THE WIFI PAGES

NEW CLICK HERE FOR THE TOYOTA RAV4 PAGES

Tuning your DCOE style Carburetor

| So you have a nifty Weber DCOE or S&K Racing sidedraft carb,

set up for your vehicle, you're ready to chew gum and kick butt, and

you've run out of gum. You bolted on the carb in place of your SUs or

Zenith-Stromberg and voila! You have worse gas mileage, and the power

gain is slight enough to be psychological. What to do?

Next, set your timing! Make sure your ignition system is good from one end to the other. Get rid of those old fouled plugs, check dwell and advance, and make sure nothing is intermittant. Set everything to book values, unless you have a firm grasp of what's better for your car. One issue with Weber conversions is vacuum advance signal. If your distributor took vacuum from the manifold, you should do the same with the new manifold. You may have to modify it, or use a port intended for a less important function such as pollution control (pollution control mods should be done only for off-road vehicles). If your distributor took vacuum from the carburetor, you should probably just ignore it. The S&K Racing carb does offer a throttle-plate vacuum port which you can try. A system with no vacuum advance will require more initial mechanical advance than book values for part-throttle tractability. Start with 5 degrees more, you may end up with 10 degrees more. Finally, set your idle mixture. Maximize RPM with the idle mixture screws, then reduce idle speed to 850-1000 (lowest smooth idle speed) with the idle speed adjustment screw. Tweak the idle mixture screws again at this speed. Repeat until no further idle speed increase is observed.

|

| Road tests:

Use timed road testing to set advance. Stop when you are at best time for the runs which reflect your desired driving pattern. To reduce variability, use Wide Open Throttle wherever possible, make your runs on level ground, and do multiple runs in both directions. Please do all this in an open area with good visibility, and slight or no traffic. The road which runs along the river or coastline is a good bet. Consider that you want your average speed over the course to be similar to or slightly below the speed limit. That will attract the least attention and tie up the least traffic. Note: This consideration is why 0-60 testing on open roads is NOT recommended. Pick a narrower speed range. Use a STOPWATCH, not a regular watch. You'll need to record times to about 0.1 seconds. Use a buddy to time if at all possible while you concentrate on driving in a consistent manner over the same ground, and looking for other traffic! Try to run all your timed runs in the same basic temperature conditions (10F temperature degree change is worth about 2% change in air density, and so mixture). Also, try to maintain a similar weight in the car (with or without a timing partner, full gas tank vs nearly empty, bags of cement or cases of Old Clem's Joy Juice in the trunk, etc). If you are shooting for best mileage, your tests should consist of sustained runs at the speed and over the terrain you plan to use. Testing with a normal mix of highway and around town can be misleading since your mind-set affects your gas pedal usage. Changes of less than 2 or 3 mpg in a normal mix can be ascribed to psychology as much as physics. So, you should fill the tank, drive at least 1/4 of a tank at sustained speeds, and then check the mileage. Now you should have a set of benchmark results for further use. Open up the access port in the top of your carb, and remove and inspect the main jet assembly. The part/size numbers are stamped on the side of each component. Record all numbers. |

|

DCOE Thumb rules (use as a starting point):

In general, for racing, the air

correction jet will be smaller than the thumb rule above, and

the main jet larger. This allows for more fuel flow

over the whole range, and further enrichment at high RPM. |

|

Optimizing for power: So, out we go to our test road. Warm up the engine completely (I drive for 6 miles to get to my test road) and make sure the air pressure in the tires is right, and fill the tank. First, run another benchmark series to get a baseline for current weather conditions. You should have enough practice by now to evaluate your runs for consistency. The main jets are the easiest to work with, so we'll try them first. They are in the tip of the jet assembly, and have a pointed "nose". Increase the size one step at a time, and run a benchmark series. If you were running too lean, you will notice a decrease in time spent above 3000 RPM. If you go too rich, the sound of the engine will change dramatically, and times increase. Go back to the next leaner size, and do another run to confirm the problem and clear the plugs. The air correction jets are in

the TOP of the jet assembly, and require that you

separate the threaded portion from the emulsion tube. Be gentle... grasp

the components to separate in PADDED pliers and wiggle them apart.

Twisting doesn't help much as these are press-fit and not threaded

joins. You will |

|

Now we get into aspects of carburetor performance which are transient or harder to quantify. We move away from the known setting of Wide Open Throttle to gas mileage and throttle response. In highway cruising at legal speeds in most of our vehicles, the throttle is mostly closed. This is because the gear is high, the RPMs are relatively low, and the horsepower requirement is 10% or so of maximum. This causes the main jet to be shrouded and so most of the gas being used is coming through the idle jet and progression holes. Overall flow to idle port and progression is controlled by the idle jet/emulsion assembly. Flow out the idle port itself is further restricted by the idle adjustment screw. Fuel is pulled from this port by airflow through the main throat. It will be a somewhat trivial portion of the fuel flow above idle. Fuel flow through the progression holes is significant above closed throttle but becomes less so after the edge of the throttle plate clears the progression holes. This is because fuel is drawn from the progression holes by high-speed air flow past throttle plate. As the throttle plate moves away from the progression holes, less fuel is drawn from them. At this point the main venturi is becoming unshrouded and more fuel is flowing through the main jet.

Modification would involve:

How do you determine all this rot? You need to see what your mixture is at your normal cruise speeds. The only way outside a dyno is to do plug cuts after sustained operations at those speeds. This means you turn off the engine and take it out gear after a sustained test at speed. Coast to the side of the road and pull the plugs... comparing color. You are looking for a chocolate brown or dark grey for all results. White is too lean, and black is too rich. Light brown/grey is also somewhat lean. A note on plug cuts.

High-performance spark plugs such as Champion Gold and other high

temperature, anti-fouling plugs, can make it hard to read plug color.

You want to have the standard temperature range plugs installed for

thest tests. In addition, oil fouling will mask true mixture color. If

you get oil fouling on your spark plugs, fix >that

When you have a relatively even color across the speed/RPM range, fill the tank with gas and drive normally. With luck you will have increased your part-throttle cruise mileage noticably! Your mixture control will be better across the operating range and your engine will be happier because of it. ----------- end of economy optimization ----------------- |

|

Now we get into an even more subjective

optimization... Well, now that you've optimized the mixture curve

over normal driving / racing parameters, you have probably virtually When the throttle plate opens

suddenly, airflow slows down suddenly. Bernoulli tells us that suction

in the venturi is caused by the air in the

venturi travelling quickly. When the air slows down, the

suction decreases, and less fuel is pushed into the throat

of the carb by ambient pressure. When you move the throttle plate open, a linkage pulls on a spring. This spring moves a piston which forces fuel into the accelerator jet chamber, and through the accelerator pump jet, through a metering hole, and into the throat of a carb. Fuel not used drains back into the float chamber through a small drainback hole.

So what do we do

now?

This shows that fuel volume is insufficent for fast throttle movement. We increase accelerator pump volume / unit time most easily by enlarging the metering hole (this item is as easily accessible as the main and idle jets). Use a pin vise and a set of drills 61-80 to gradually enlarge the metering hole. On the MGB, I started about 77 and ended up at 69. More may be required as I get used to the difference. Try to reproduce realistic transitions, from realistic RPMs, in all the gears. You may notice as you enlarge at some point the initial response is good, then a short bog before things kick in. This means the duration is too short. If you see this problem at extremely low RPMs, you may want to re-evaluate your requirements. Do you need to SLAM the throttle from 1400 RPM? In any case, stop enlarging the metering hole if you run across this problem. Going any further will require modification of the drainback hole to provide a bigger fuel supply.

|

Intial Setup and adjustment of a Pair of DCOE 40's on a 1500

-

Make sure that the CHOKE lever is pushed in fully.

Check that the choke cable is allowing the enrichment levers on the back of the Webers return to their stops. Loosen the clamps with a 7mm wrench and push the levers to their stops. Tighten the clamp screws.

-

Check the FUEL HOSES for cracks (especially near the ends) or leaks.

-

Empty the water separator and inspect or replace the FILTER.

-

Check for FULL THROTTLE OPENING.

Have a helper step on the accelerator pedal while you watch the throttle shafts rotate to the fully open position. Adjust the linkage, if necessary. Make sure that the bellcrank under the carbs is not sticking on its shaft.

-

Synchronizing the throttles.

Make sure that the throttles are synchronized. Remove the brass plug (above the off-idle holes) of each carburetor section. Shine a flashlight into each of the holes to see that the edge of each throttle plate is aligned with the same hole when the throttle is slightly open. Adjust the spring-loaded screw in the linkage between the two Webers. Make sure that the Idle Stop Screw is NOT against its stop when you are making the adjustment or you will be even more confused.

-

Check the FLOAT LEVEL.

-

Remove some fuel from the carbs and let the engine idle for two minutes. Remove the wingnut caps.

-

Use the depth gauge end of vernier caliper to measure from the top of the lower shelf to the top of the fuel surface.

-

Check for Air leaks

Check for Intake System AIR LEAKS while engine is running Wiggle the carbs and pour water on the donuts and listen for a change in the engine speed.

-

Adjust the IDLE MIXTURE.

DCOE spec = 1.14 inch (29mm+4.5mm).

If the depth is NOT correct, the top plate of the carburetor must be removed. Carefully bend the tab on the float assembly that touches the needle valve. Reassemble and test the float level as before.

Raise the idle speed to 1000-1500 rpm by turning the Idle Stop Screw. Stop the engine. Remove the spark plug wires from the two rear spark plugs and ground the wires. Turn each of the front two Idle Mixture Screws clockwise and count the number of turns until the Idle Mixture Screw touches its seat. Normally, this screw is about 3/4 of a turn from its seat.

Restart the engine. Adjust the two front idle mixture screws so that the engine rpm is the highest possible. Allow a few seconds after each adjustment for the engine to respond to the change.

Stop the engine. Reconnect the two rear plug wires, disconnect, and ground the two front plug wires. Adjust the two rear idle mixture screws.

NOTE: The idle speed should be the same when the engine is running on the front two or on the rear two barrels.

Stop the engine and reconnect the wires. Turn the Idle Stop Screw clockwise to the original position. Start the engine.

-

Adjust the IDLE SPEED.

Adjust the idle speed by turning the Idle Stop Screw. If the idle is too high when the Idle Stop Screw is NOT touching its seat, the throttles are NOT returning to the closed position. Make sure that the linkage is not binding.

Supplied to the manafacturers to be used as OEM carburation for each of the cars listed, this table shows the factory jetting info as configured as 'stock'.

| Model | 40 |

40 |

40 |

45 |

45 |

45 |

45 |

45 |

|

style (or sub model #) |

18 |

32 |

2 |

9 |

9 |

13 |

13 |

15/16 |

|

mfg. part number |

19550.013 |

19550.043 |

18550.005 |

19600.017 |

19600.027 |

19600.003 |

19600.022 |

19600.004 |

|

Choke |

30 |

32 |

33 |

36 |

38 |

38 |

34 |

38 |

|

Aux. Venturi |

4.5 |

4.5 |

4.5 |

4.5 |

3.5 |

5 |

3.5 |

5 |

|

Main Jet |

115 |

130 |

115 |

145 |

175 |

160 |

130 |

125 |

|

Emulsion Tube |

F11 |

F9 |

F16 |

F16 |

F2 |

F16 |

F2 |

F9 |

|

Air Jet |

200 |

200 |

150 |

155 |

170 |

170 |

175 |

170 |

|

pump jet |

40 |

35 |

35 |

45 |

40 |

50 |

50 |

40 |

|

Idler jet |

45F9 |

50F8 |

50F9 |

55F8 |

70F6 |

45F9 |

50F9 |

45F8 |

|

pump bleed |

50 |

60 |

55 |

40 |

closed |

100 |

50 |

70 |

|

needle valve |

175 |

150 |

200 |

200 |

200 |

225 |

225 |

225 |

|

float level |

8.5/15 |

8.5/15 |

8.5/15 |

7/13.5 |

-3 |

-3 |

-3 |

7.5/14 |

| (intended use) |

Lotus Elan & Cortina |

Alfa 1750 | Maserati 3500 GT |

Alfa

Romeo 2600 |

? | ? | ? | BMW 1800 |

Conversion Kits

From Weber's own guides, the following table is a list of the standard

jettings

as supplied in their conversion kits. The kit #'s are also listed in the

table.

| Conversion Kit number |

application | Carburetor and qty. |

Main Venturi |

Aux. Venturi |

Main Jet |

Emulsion tube |

Air Corrector Jet |

Idle Jet |

Acc. Pump Jet |

Pump Ex. Valve |

| K009 | Sprite Midget 950,1100cc |

1 of DCOE 40 2 |

32 | 4.5 | 140 | F2 | 175 | 45F9 | 50 | Closed |

| K011 | Sprite Midget 1275cc |

1 of DCOE 45 13 |

34 | 3.5 | 130 | F2 | 175 | 50F9 | 50 | 50 |

| K041 | MGA | 1 of DCOE 45 13 |

34 | 3.5 | 145 | F16 | 160 | 50F9 | 50 | Closed |

| K043 | MGB 1963-74 |

1 of DCOE 45 9 |

36 | 4.5 | 150 | F16 | 170 | 50F8 | 60 | Closed |

| K044 | MGB 1975-80 |

1 of DCOE 45 13 |

34 | 3.4 | 145 | F2 | 165 | 50F9 | 50 | 50 |

| K124 | Midget Spitfire 1500cc |

1 of DCOE 40 18 |

28 | 4.5 | 125 | F16 | 160 | 45F9 | 50 | 50 |

| K125 | Midget Spitfire 1500cc |

2 of DCOE 40 18 |

30 | 4.5 | 115 | F16 | 170 | 45F9 | 50 | 50 |

| K126 | Midget Spitfire 1500cc |

1 of DCOE 45 13 |

34 | 3.5 | 150 | F2 | 175 | 55F8 | 50 | 50 |

| K131 | Triumph TR3,4 |

2 of DCOE 40 18 |

32 | 3.5 | 140 | F15 | 150 | 50F2 | 50 | 50 |

| K143 | Triumph GT6 1969-73 |

3 of DCOE 40 18 |

30 | 4.5 | 120 | F2 | 160 | 50F11 | 45 | Closed |

| K151 K153 |

Triumph TR6 | 3 of DCOE 40 18 |

30 | 4.5 | 120 | F11 | 160 | 50F11 | 40 | 50 |

| K161 |

Triumph TR7 |

2

of DCOE 40 18 |

30 | 4.5 | 125 | F9 | 155 | 55F8 | 45 | 45 |

The DCOE numbers....

.....a project in process. data is in complete and constantly being updated.......

From the eyes, ears, minds, and typing fingers of the members of the Triumph Spitfire e-mail List, The Editors of the Triumph Tune Catalog, with a special thanks to those people submitting photos and jetting info that makes these pages possible, I bring you a compilation of all the info I've been able to find concerning the initial setup of Weber DCOE carburetors for the 1500 Triumph Spitfire (and now others...post 11/99).

There are many factors that can effect the initial settings that work best for you. They vary due to driving habits, various engine modifications, state on wear, etc ,etc.

Get your hands on a copy of 'Weber Carburetors' by Pat Braden, ISBN #0-89586-377-4. It covers dis-assembly and rebuild, tuning, and complete descriptions of all the sub-sections of the inner workings of the DCOE, among others. Also the Haynes Weber Manual (?? ISBN #???) is a very good source of info. A third source is the Weber Factory Overhaul Manual (Weber part number #95.0022.35). You can order this book from The Performance Parts Warehouse Another excellent sources is Advanced Performance Products they carry a complete line of ram pipes, jets, air filters ands ancillaries for the DCOE.

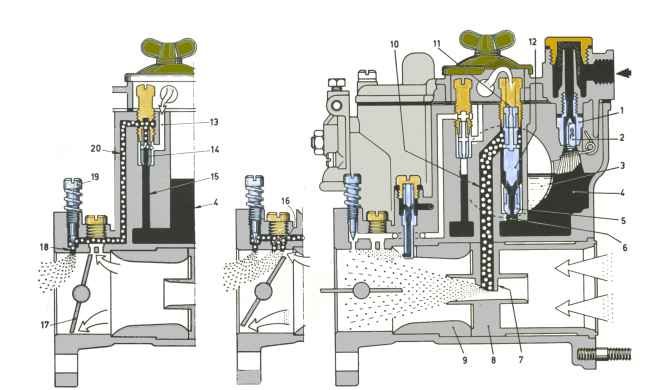

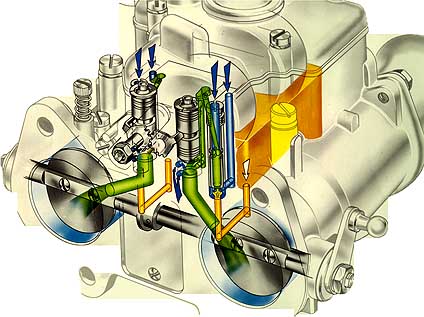

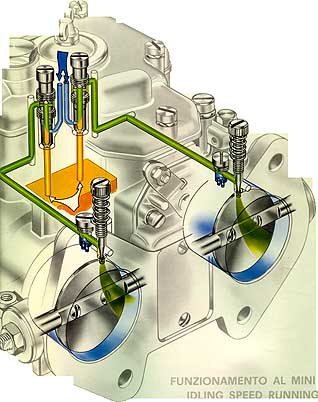

The Flow Paths of the Fuel

| If idle jet size is correct, the idle mixture screw (19) will be 1.5 to 2.5 turns out from full closed. |

Progression ports, |

Pump Jet, idle, and Main Jet |

| The idle stop screw should have the

throttle plate (17) sitting just at the edge of the first 'progression hole. |

Just off idle and full speed cruising |

|

WEBER CARBURETORS A Technical Primer By:

"If you have always wanted to know what makes these carburetors so special, here's a basic, easy-to-understand introduction to the world of Weber exotica."

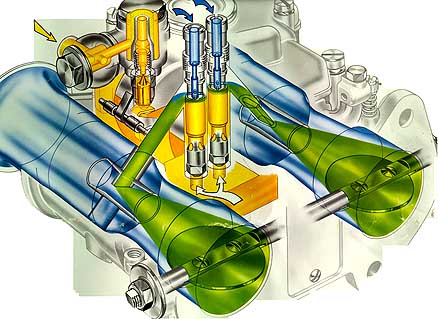

Weber carburetors have been seen as standard equipment on the finest racing and street machinery to come out of Europe for over three decades. Maybe you've been lucky enough to get a ride in a Ferrari or a Weber carburetor 289 Cobra; if you have, chances are, it's a ride you've never forgotten! Weber-carburetor engines all have one thing in common: they assault the senses with a rush of torque and a brutal sense of urgency that is generally unmatched among carbureted engines (and they have a sound all their own...go to a Shelby American convention on Open Track day and you can pick out the Weber-carbureted Cobras just by their sound; there is no mistaking it!). The world's most beautiful, exotic and most powerful engines have traditionally been fed through Weber carburetors. But why Weber? For starters, it's a modular carburetor design. It is produced in a wide variety of styles which incorporate different features, enabling the user to select exactly the right design and size for the intended use. You can even change its CFM to suit your needs, which should begin to explain the Weber's superior adaptability for all kinds of applications. Now, if you're one of those people who has always had trouble accepting the idea that the Weber is a terrific street carburetor, consider it this way: Weber carburetion is like an expensive musical instrument. If it is not tuned properly, that instrument will never make beautiful music for you-no matter what! And therein, lies the secret of making beautiful music with Weber carburetors-initial preparation...... It's what "tuned induction" is all about! THE CONCEPT The Weber carburetor was designed to be totally adaptable to any size engine, for any purpose, at any altitude. There is no such thing as taking four of these out of their boxes and bolting them on to an intake manifold...it simply isn't done that way. This carburetor was intended for serious tuners and performance enthusiasts who want the most that their engine can give them. Welcome to the Big Time! TERMINOLOGY All Weber carburetors carry a basic model number which is stamped at the base of the carburetor on its mounting flange. The most well-known is the good-old "48 IDA", a masterpiece of design and a marvel of precision machining that has been around since the early 60's with only minor revisions. In this case, the number 48 indicates the carburetor's size. It tells us the carburetor has a bore diameter and throttle plate size of 48 millimeters (about 1 15/16"), while the IDA suffix tells us that it is a high performance downdraft carburetor. There is also a 40 & 46 IDA/3C. Again, a high performance downdraft, available in 40 and 46 mm sizes. The 3C means this one's a "3-choke" (the in-line three barrel). The 40, 42 and 44 DCNF's are compact twin-throats which feature a cold-start. As the prefix numbers indicate, they are available with bore diameters of 40, 42 and 44 mm. Then there are the sidedrafts - all Weber sidedraft carburetors carry the suffix DCOE, their prefix numbers (sizes) ranging from 38 mm all the way to 55 mm (that's close to 2 1/4"). So you see, all those numbers and letters really mean something. It's all pretty simple.....So, the next time someone mentions he's running Weber's, ask him whether he's running DCOE's or IDA's and pick up a few bench-racing pointers. THE VARIABLE CFM FEATURE Some where along the line, you can probably recall seeing four 48 IDA's on a big, nasty rat motor. You've also probably noticed that the same four 48 IDA setup is used on 289 Ford engines, as on the Cobras, for instance, You may have wondered how the same carburetor setup could work on two such vastly different engines. It seems that one engine would have to be either over or under carbureted, if we assume that the carburetion is "right" on one engine. Actually, this isn't true at all, because either engine is running the same set of carburetors as the other. Assuming the Webers are set up properly, the only thing the two systems will have in common is their outward appearance. The Weber's most interesting design feature is it's removable "choke" or venturi, allowing it to be instantly converted from a large-CFM carburetor to one of small CFM, or vice-versa. By installing a smaller choke, the carburetor is constricted and it flows less CFM, to make it perform in the midrange, or to make it suitable for use on a low-compression small block engine. Pull out those small chokes, drop in some large-diameter ones, which may be nothing more than thin-wall "sleeves", and you've got a set of 48 IDA's that will flow enough CFM to make a big block scream. But don't try putting those "big" carburetors on the small block motor! It will fall flat on it's face, lack throttle response and become a complete nightmare in traffic("....My buddy had a set of those Webers on his engine, and boy! did that car run badly!!!!!"). In order to get drivability, throttle response and lots of torque from the Weber-carbureted engine, the choke size, therefore, is the first consideration. How big is the motor, what's the compression ratio and what do you want to do with it, once the correct size choke has been selected for your application, the jetting for all the rest of the circuits can be established around that choke size. THREE CIRCUITS For the sake of simplicity, let's look at the Weber carburetor as having three basic circuits- the idle circuit, the accelerator pump circuit and the main circuit. The idle circuit is comprised of two components, the idle jet and the idle jet carrier. With these two pieces, the tuner can select exactly how much fuel and how much air he wants to provide the engine at idle and during the low rpm operation, while making very fine adjustments to either, if necessary. The idle mixture is delivered as a proportioned mixture whose total volume can be further regulated with the idle mixture screw, which is located on the lower part of each carburetor barrel. On a correctly-jetted idle circuit, the mixture screw on a 48 IDA is never more than 3/4 of a turn out. This will hold true 100% of the time, no matter what anyone else tells you. If you have to go more than that, you'd better heavy-up the idle jet. Even if you get it to idle, going more than 3/4 turn tells you the jet is lean and you're going to have other drivability problems, which brings us to the next part of the idle jet's function. The idle circuit in the Weber isn't just an idle circuit - it does more than that. It is actually the circuit which must carry the engine all the way up to about 2,800-3,000 rpm, where the transition to the main circuit take place. That means if you don't drive over 3,000 rpm, you're only running on the idle jets. After 3,000 rpm or so, the idle circuit is entirely bypassed and no longer has anything to announce. So, if you have a tuning problem that "goes away" after about 3,000 rpm, that tells you to play with the idle circuit. Or maybe the opposite is true. Either way, it's very cut and dried as far as the two circuits are concerned - so isolating the problem is a breeze. One the most frequently experienced "gremlins" with Weber carburetors is a seemingly incurable and very annoying flat spot which rears its ugly head at about 2,200-2,800 rpm. This condition is generally caused by one of two things - you either have the wrong emulsion tube in the carburetor, which is causing a rich stumble due to an under-emulsified mixture at that particular rpm range or the idle circuit is falling off too early to carry the engine up to the point where the main circuit can take over, leaving a "lean hole". In simple terms, the idle circuit is going lean too early. Either condition is easily rectified. In the case of the emulsion tube, there are really only a few which work really well for V8 applications; and if you aren't using one of them it is certainly a big part of the problem. If the flat spot is still there even with the correct emulsion tube, then you'll need to richen up the idle circuit. This is sometimes a tricky area, because the first thing you want to do is throw in a bigger idle jet, but sometimes playing with air bleeds, mixture screws, or choke sizes can accomplish the same thing while sticking with the original jet size. Seeking a little bit of sound advice here can save a lot of time and hassle. The point here is that these carburetors are designed to come off idle and run smoothly all the way up. Your problems can be solved with a little tuning on your own or by relating the symptoms to someone who is knowledgeable enough to help you. Remember, these carburetors will do just about anything you want them to, except maybe wash your socks. The accelerator pump circuit, just like on any carburetor, is responsible for eliminating "bog" and making a passing maneuver without a hesitation or stumble. The circuit also has two basic elements. These are the pump exhaust valve and the pump jet. The pump exhaust is nothing more than a bypass valve and this is located in the bottom of the float bowl. This is the piece that regulates how much fuel you want to make available when you need that pump shot. Putting a bigger bypass hole in the valve allows more fuel to bleed back into the float bowl instead of out of the shooters. The smaller the hole, the more fuel you're making available. You can even put in a "closed" bypass for drag racing, when you need all the juice you can get in order to get those slicks turning. Obviously, there is nothing complicated about a simple bypass system. The duration of the pump shot is varied by installing a larger or smaller pump jet (shooter). Larger pump jets give a heavy blast over a short period, while the smaller ones will give a finer, longer-duration shot. As long as you leave the bypass valve alone, you're still getting the same overall volume. In most cases, the stock pump jets can be left alone. The main circuit is the easy one. This is where you make your power. This circuit has three primary elements you should concern yourself with - the main jet itself, the emulsion tube and the air corrector. You're thinking that's a lot of pairs - usually, it's just a main jet. You know how to "read" what your Webers can tell you on a road test, you wouldn't have it any other way. The capability for fine adjustment is what you pay for. Let's take a look at this main circuit...... The main jet is stuck into the bottom of the emulsion tube and sits in fuel. As the carburetor begins to work, the main jet meters the amount of fuel allowed to pass through it and up into the "main well" around the emulsion tube. Air enters the top of the emulsion tube through the air corrector which meters the amount of air to be mixed with the fuel. The air blows out of the emulsion tube through a series of holes along its length and aerates the fuel that is rising up the well around the tube. This emulsified mixture is then sucked out of the main delivery nozzle as the "depression" in the carburetor increases to the point where it's strong enough to pull it out. This occurs by 3,000 rpm or so, and you're down the road like a shot. Tuning the main circuit for maximum power is something that can be done by a series of road tests and a handful of jets. The simple rule of thumb for jetting Weber carburetors is, if you want to implement a change over the entire rpm range, you play with the main jet. If you want to change the way the car feels at the high end, that's where the air corrector comes in. Also, you should keep in mind that the air corrector is a finer adjustment that the main jet. Example: One step upward in the main jet (richer) equals about the same as three steps down on the air (less air: richer). A change of air corrector would be appropriate; for instance, if the engine pulls strong to 5,000 rpm and then goes flat. This would mean she's going lean on you up top; drop the air corrector three sizes or so, and you'll probably be able to buzz that engine right up to 7,000 rpm. If the motor feels sour all the way up, go one or two sizes heavier on the mains only. No magic! So, tell me, what's so hard about jetting these Webers? STREETABILITY Most people don't realize that this carburetor, like all highly efficient items, is an extremely simple design with very few moving parts. There are no metering rods, power valves, rubber seals or plastic parts. The accelerator pump on the 48 IDA is a brass piston. The throttle shaft rides in a set of precision roller bearings. Webers use brass floats, which cannot become fuel-logged, and gradually sink with age. It is a superior example of precision machining and "beautifully-fitting" components...it's really very unlikely that one of these carburetors is going to "fail" and cause you to be stranded somewhere. That's another reason why they're well suited to street use and long-distance cruising - they are extremely reliable. With the infinite tune ability of Weber carburetors, there is no need to compromise the drivability or road manners of your car. If you know someone who suffers from drivability problems with such a nice carburetion system, he is doing so unnecessarily. A Weber unit should be crisp, responsive and smooth. If it is not, something is wrong - let's just say he's not through tuning it yet, that's all! The first thing most people notice when they go to Webers is an increased flexibility from the motor. There is a natural tendency for a Weber-carbureted engine to idle smoother, have a slicker "feel" to it a low speeds (particularly if a hot camshaft prevented that feeling before), and generally feel much more powerful throughout the entire rpm range. This is largely because they use an independent-runner manifold, which does not incorporate a plenum. In a typical four two-barrel Weber layout, there is one barrel directly feeding each cylinder without any intercommunication between barrels or cylinders. This totally "isolated runner" design ensures that each cylinder is fed exactly the same as the next, without any chance of charge-robbing or over-feeding. What you are doing, in effect, is separately tuning each cylinder. This results in a dramatic increase in horsepower output and torque in midrange, right where street engines spend 90% of their time, making this an ideal carburetion system for street use, where maximum flexibility creates greater driving enjoyment. The throttle response with an independent runner induction system is also a new experience, it's second to none. A Weber carburetion system will respond like a fuel injection unit, with which it shares some similarities: short runner length, isolated design and essentially a low fuel mass to move when you hit the throttle. (Remember, you're not asking that cylinder to gulp all the mixture from that big plenum area - that's a lot of mass, by comparison. The only mass to move is what's in that one short runner). The main difference between fuel injection and Weber carburetion is that one relies on fuel being injected under very high pressure, while the other responds to the needs of the engine via the depression principle. For street use, the Webers have the edge - it's what they were made for. In the mileage department, it really depends on the rest of the engine and your driving habits, but 16 to 18 mpg is not unusual on the highway. This is pretty respectable, when you stop to consider that the engine is fed by all eight barrels constantly. There is no such thing as a progressive system here. Another thing: Webers will run happily on regular gas. If you can run regular now, you can continue doing so after installing the Webers. This is purely a function of compression ratio and ignition timing, not induction. In fact, if you're running a 10.5:1 engine, you may find it's a little bit fussy about which brand of fuel it wants. giving you detonation at times. Generally speaking, the Weber carburetion will likely change this for the better, suppressing the tendency to "ping". One reason for this phenomenon is that the fuel distribution is now fully controlled, eliminating the "lean spots" which sometimes are present in conventional manifolds which distribute fuel from a central plenum. Lean cylinders run hot - excessive cylinder heat means detonation. TUNING AND MAINTENANCE A Weber carburetion system will not be right, unless it's synchronized to ensure that each carburetor is doing exactly the same as the next - the name of the game is perfect cylinder tuning. The synchronization procedure can either be a breeze or a nightmare, depending on whether you have a well-designed linkage system or not. The secret to a good linkage setup is that it must allow independent adjustment of each carburetor without affecting all the rest as you go through the procedure. Here again, if someone tells you they're absolutely impossible to synchronize, you might study his linkage. Chances are, it's incorrect and he's fighting himself. The right components are now available to take this out of the dark ages. The final idle mixture adjustment on each barrel is a simple adjustment which is performed by ear, but because there are four carburetors, a lot of guys feel intimidated. It's done the same way you do a single four barrel, except in this case, you can listen to each cylinder separately. It may take you four times longer, but it's no more difficult at all. Each mixture screw, as it is turned, will have a noticeable effect on engine rpm, as the wrong setting will cause the cylinder to "go away" - it's just like pulling a plug wire. No matter how hard you try, you can't mess this up if you remember one thing: always start from scratch at 3/4 turn out. From there, you go 1/8 of a turn either way and it's usually in, not out. This will get you out of the woods if you ever get lost. Once the unit is synchronized and the idle mixtures are dialed in to give you the smoothest possible idle, you can hang up your Unisyn and screwdriver til' next spring, because now it's set! And when it's set, it's set!! They will not suddenly "go out" on you and ruin your day at the picnic. EXPENSE When it comes to the Price of Admission to "Weberdom", what can one say...... Webers are not for everyone. This type of induction unit represents a sizeable investment. It's still possible to put a unit together on your own with bits and pieces, and if you're a fast-lane spender, you can opt for a ready-to-run unit created especially for your engine. Dollarwise, Webers usually fall into the category of a supercharger with carburetors. The price of opening up a box and pulling out a science-out Weber unit with all the right pieces and associated hardware will run you from $3,000.00-$4,000.00, depending on how much flash you have to have. Sound expensive? Maybe not, if you consider that all things are relative. When you figure the price of a top quality paint job at $5,000.00 to $10,000.00, a completely redone interior at $3,000.00 to $5,000.00, a set of trick wheels and tires at maybe $3,500.00, and your basic "nice street engine" at $3,000.00 to $5,000.00, another two grand for an item that changes the car's whole personality falls right in line. And as they say, "the fun's in the driving". Weber carburetion is a lot more than something that's exciting to look at. Every time you take that machine of yours down the road, you become more aware of your engine's ability to do everything it should do with a minimum of fuss. Throttle response, quick acceleration and overall flexibility are the constant reminders of what you've spent your money on - the ultimate carburetion system! |

40DCOE2

(from Weber General Catalog 1/5/1961)

NORMAL

OPERATION:

| The fuel arrives through the needle valve (1) to the bowl (4) where the float (3) controls the opening of the needle (2) in order to maintain a constant fuel level. Through the ducts (6) and the main jets (5), it reaches the emulsioning tubes (12) from which after having been mixed with the air coming from the air corrector jets (11), through the pipes (10) and the nozzles (7) it reaches the carburation area consisting of the auxiliary Venturi's (8) and chokes (9). |

STARTING DEVICE

| The fuel

flowing from the bowl (4) arrives to the starting device through

the ducts (32) and the starting jets (30). Emulsified with the

air coming from the hole (29) it reaches the valves opening (35)

through the ducts (31) and definitely emulsified by the air

entering from orifices (34) is then carried by means of the

ducts (33) to the carburetor throats below the throttles.

|

|

Engine cold starts: starting device inserted (position A) Engine starts half warm: partial insertion of the device (position B) Engine warm ups: during engine

warming up, even if the vehicle is under way, Normal operation: starting device

must be pushed back as soon as the engine |

- 1 Make sure that the weight of the float is the correct one (26 grams), that the float can freely slide on the axis and does not show any pits.

- 2 Make sure that the needle valve (v) is tightly screwed in its housing and that the pin ball (Sf) of the dampening device incorporated in the needle (S) is not jammed.

- 3 Keep the carburetor cover (C) in a vertical position as indicated in the above figure, since the weight of the float (G) could lower the pin ball (Sf) fitted on the needle (S)

- 4 With carburetor cover (C) in vertical position and float clip (Lc) in light contact with the pin ball (Sf) of the needle (S) the distance of both half-floats from upper surface of carburetor cover (C) with gasket (Gz) in place, must measure 8.5mm.

- 5 After the leveling has been done, check that the stroke of the float is 6.5mm. If necessary adjust the position of the lug (A).

- 6 In case float (G) had not been rightly set, rectify the position of float clip (Lc) till the required quota is reached, taking care that the clip (Lc) does not show any pit on the contact surface that could affect the free sliding of the needle.

- 7 Fit up the carburetor cover making sure that float can move with out any hindrance or friction.

Idling Operation and Progressive Action

| The fuel is carried from the bowl (4)

to the calibrated holes of the idling jets (14) through the

ducts (15). Emulsified with the air coming from the ducts

(13) through the ducts (20) and the idling feed holes (18)

adjustable by means of screws (19) the fuel reaches the

ducts (20) the mixture can reach the carburetor throats also

through the progression holes (16) |

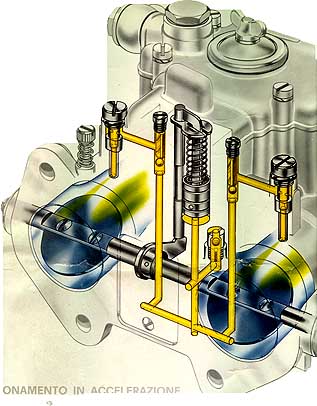

ACCELERATION

| By closing the throttle valves, the lever (25) , by means of the shaft (27), lifts the piston (26). the fuel is thus drawn from the bowl (4) into the pump cylinder through the suction valve (23). By opening the throttles, the shaft (27) is free and the piston (26) is pushed down under the action of the spring (28), by means of the ducts (22) the fuel is injected into the carburetor throats. The inlet valve (23) is provided with a calibrated hole which is discharges the excess fuel delivered by the accelerating pump in to the float bowl. |

SETTING THE FLOAT

|

NOTE: the operation of leveling of the

float must be carried out whenever it is necessary to

replace the float and needle valve: in this case it is

advisable to replace also the sealing gasket, making sure

that the new needle valve is tightly screwed in its housing.

|

EXPLODED VIEW

PARTS LOCATION

| 5. Idle jet holders 7. Idle air orifices 16. Additional Air Horns 18. Pump inlet valve 29. Idle mixture adjustment screws 30. Pump jets 34. Pump control rod 39 Spring guides and retainers 42. Mixture ducts 43. Starting Jets 45. Starting jet wells 61. Pump deliver vlave 62. Progression holes inspection screw 63. Emulsion tubes complete with main jets and air corrector jets 64. Air Horns mounting plate. 65. Bowl plate 66. Idle speed adjusting screw 66. Idle speed adjusting screw 67. Throttle control lever 68. Retainer Washers 69. Pump Spring retainer plate 70. Throttle return spring retaining plate |

40DCOE3

SETTINGS

FLOAT SETTINGS

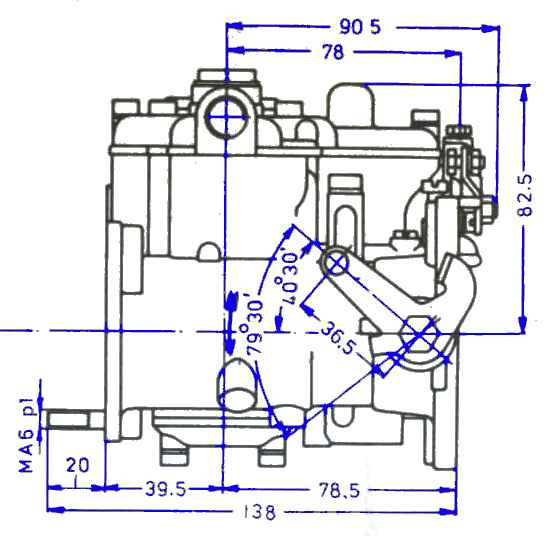

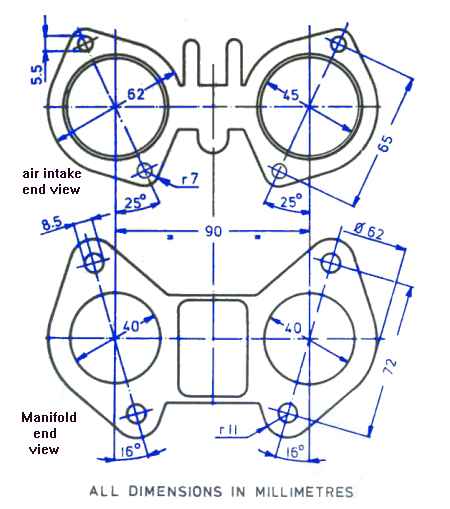

Here are the physical

dimensions of

the body of the DCOE carburetor.

All dimensions are in millimeters

You are

viewing

the carb

from the

manifold

mount

flange

end.

You are

viewing

the carb

from the

fuel port

side.

| These are the mating surfaces |

![[Most Recent Quotes from www.kitco.com]](http://kitconet.com/images/quotes_7a.gif)