WE WELCOME OUR NEW SITE SPONSOR CAPITAL ONE!

![]() CLICK HERE TO DONATE TO HELP FUND THIS SITE!

CLICK HERE TO DONATE TO HELP FUND THIS SITE!

NEW CLICK HERE TO SEND US A GIFT! A COOL IDEA TO HELP US FOR HELPING YOU!

NEW CLICK HERE FOR THE AMAZON PRIME PAGES!

NEW CLICK HERE FOR HOLIDAY CARDS AND WRAPPING PAGES

NEW CLICK HERE FOR THE UPS PAGES

NEW CLICK HERE FOR THE 2000 4.1 TOYOTA RAV4 PAGES

NEW CLICK HERE FOR HOME AUTOMATION PAGES ALEXA AND FIRE TV AND GOOGLE HOME ITEMS

NEW CLICK HERE FOR Y 3 K PAGES

NEW CLICK HERE FOR THE HOUR METER PAGE

CLICK HERE FOR THE FITTINGS ID PAGES FOR HOSES AND PORTS

NEW CLICK HERE FOR HYD ORINGS PAGES

CLICK HERE FOR THE BIG SHOP TOOLS PAGES

CLICK HERE FOR THE LISLE TOOLS PAGE

CLICK HERE FOR THE THREAD SIZE PAGE

CLICK HERE FOR THE BOLT TORQUE PAGE

CLICK HERE FOR CONSTRUCTION PAGES

CLICK HERE FOR THE WIND POWER PAGES

CLICK HERE FOR HEALTH CARE PAGES

CLICK HERE FOR TV ANTENNA AND ROTOR PAGES

CLICK HERE FOR THE ELECTRONICS PAGES

CLICK HERE FOR THE SAFETY PAGES

NEW CLICK HERE FOR LOCKS PAGES

CLICK HERE FOR IPAD IPHONE PAGES

CLICK HERE FOR THE TRACK AND TELL PAGES

CLICK HERE FOR WORK CLOTHING PAGES

CLICK HERE FOR THE LITHIUM RECHARGEABLE BATTERY PAGES

CLICK HERE FOR THE EMERGENCY LIGHTS PAGES

CLICK HERE FOR THE BELT ALIGNMENT PAGES

CLICK HERE FOR THE HVAC AIR CONDITIONER PAGES

NEW CLICK HERE FOR THE HOT WATER HEATER PAGES WITH RECIRCULATION PUMPS

CLICK HERE FOR THE WINDOW TINT PAGE WITH BLACK OUT TINT TOO!

CLICK HERE FOR THE CAMPER TRAILER LIGHTS WIRING DIAGRAM PAGE

CLICK HERE FOR THE TRAILER TOW PAGES

NEW CLICK HERE FOR THE DIESEL REPAIR PAGES

IECO 210 HP 4 CYL / POUSTUSA CHEVY VEGA PAGE

RADIO SERVICE RADIO CONVERSION AND MORE

SALVAGE YARD LINKS STATE BY STATE LISTINGS

CLICK HERE FOR EQUIPMENT AND SMALL ENGINE PAGES WITH LINKS HONDA PAGES TOO AND HOW TO!!

CLICK HERE FOR THE MOUSE TRAP PAGES A TRAP THAT WORKS FOR US!!

CLICK BELOW FOR THE COOL UNIT CONVERTER SITE

CLICK HERE FOR SHOP TOOLS AND EQUIPMENT PAGES

CLICK HERE FOR MUST HAVE TOOLS LIST PAGE

CLICK HERE FOR AIRCON SOFT START PAGES

CLICK HERE FOR THE INVERTER WINDOW AC UNITS

CLICK HERE FOR THE ELECTRICAL TOOLS AND PARTS PAGES AND MORE!

NEW CLICK HERE FOR RESTAURANT PAGES

NEW CLICK HERE FOR TRUCK CRAIN BED LIFTS

NEW AUXITO ULTRA BRIGHT LED LIGHTS

NEW SEAT BELTS FOR YOUR HOTROD AND MORE

CLICK HERE FOR THE POWER WASHER PAGES

CLICK HERE FOR THE DRAINZIT OIL DRAIN PAGES

CLICK HERE FOR THE DC FUSE PAGE ATO, ATC, MAXI, GMA

NEW CLICK HERE FOR THE SURVIVAL PAGES

NEW CLICK HERE FOR THE WIFI PAGES

NEW CLICK HERE FOR THE TOYOTA RAV4 PAGES

|

IDF / DCOE / IDA / 38 DGAS |

|

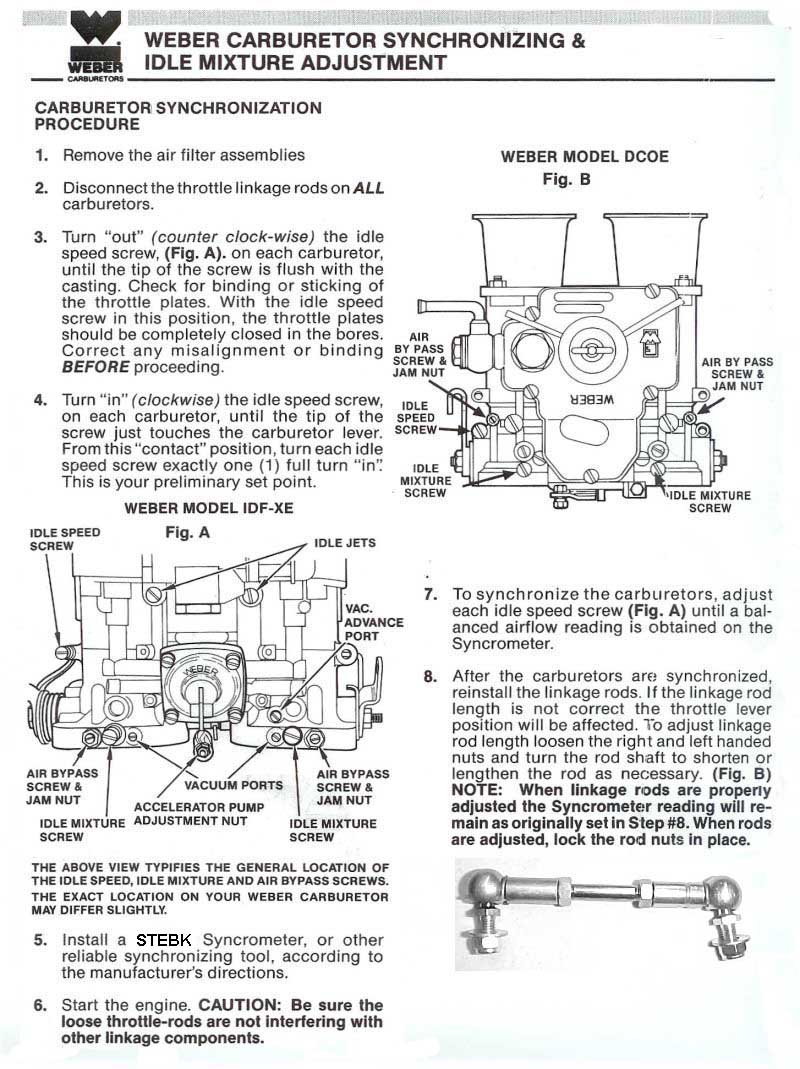

Addendum to lean Best Idle adjustments Notes and adjustments for IDF and DCOE Carburetors All adjustment procedures are the same as the

progressive carbs. It is important to understand the dynamic differences

of the two carb styles Progressive and Synchronous carbs Or

better described as individual runner carbs. Standard IDF & DCOE Settings |

|

|

FLOAT LEVEL - DGV / IDF / DCOE / DCNF / IDE-XE

The float level is a critical part of carburetor calibration. Changing the fuel level in the bowl will change the point that the main circuit starts to feed, alter the characteristics of an emulsion tube, and affect drivability and fuel consumption. GENERAL INSTRUCTIONS: Float level, in mm, typically refers to the distance from the face of the carburetor top cover to the float. With the top cover held vertically (float pivot at the top) and the float tab (Lc) resting against, but not depressing the spring loaded ball in the needle valve, measure between the face of the carburetor top cover to the top or bottom of the float. On carburetor models where it is required to remove the float to replace the top cover gasket, the measurement should be made with the gasket in place to the gasket face. |

|

|

|

DCOE |

|

|

![[Most Recent Quotes from www.kitco.com]](http://kitconet.com/images/quotes_7a.gif)