![]() CLICK HERE TO DONATE TO HELP FUND THIS SITE!

CLICK HERE TO DONATE TO HELP FUND THIS SITE!

NEW CLICK HERE TO SEND US A GIFT! A COOL IDEA TO HELP US FOR HELPING YOU!

NEW CLICK HERE FOR THE AMAZON PRIME PAGES!

NEW CLICK HERE FOR HOLIDAY CARDS AND WRAPPING PAGES

NEW CLICK HERE FOR THE UPS PAGES

NEW CLICK HERE FOR HOME AUTOMATION PAGES ALEXA AND FIRE TV AND GOOGLE HOME ITEMS

NEW CLICK HERE FOR Y 3 K PAGES

NEW CLICK HERE FOR THE HOUR METER PAGE

CLICK HERE FOR THE FITTINGS ID PAGES FOR HOSES AND PORTS

NEW CLICK HERE FOR HYD ORINGS PAGES

CLICK HERE FOR THE BIG SHOP TOOLS PAGES

CLICK HERE FOR THE LISLE TOOLS PAGE

CLICK HERE FOR THE THREAD SIZE PAGE

CLICK HERE FOR THE BOLT TORQUE PAGE

CLICK HERE FOR CONSTRUCTION PAGES

CLICK HERE FOR THE WIND POWER PAGES

CLICK HERE FOR HEALTH CARE PAGES

CLICK HERE FOR TV ANTENNA AND ROTOR PAGES

CLICK HERE FOR THE ELECTRONICS PAGES

CLICK HERE FOR THE SAFETY PAGES

NEW CLICK HERE FOR LOCKS PAGES

CLICK HERE FOR IPAD IPHONE PAGES

CLICK HERE FOR THE TRACK AND TELL PAGES

CLICK HERE FOR WORK CLOTHING PAGES

CLICK HERE FOR THE LITHIUM RECHARGEABLE BATTERY PAGES

CLICK HERE FOR THE EMERGENCY LIGHTS PAGES

CLICK HERE FOR THE BELT ALIGNMENT PAGES

CLICK HERE FOR THE HVAC AIR CONDITIONER PAGES

NEW CLICK HERE FOR THE HOT WATER HEATER PAGES WITH RECIRCULATION PUMPS

CLICK HERE FOR THE WINDOW TINT PAGE WITH BLACK OUT TINT TOO!

CLICK HERE FOR THE CAMPER TRAILER LIGHTS WIRING DIAGRAM PAGE

NEW CLICK HERE FOR THE DIESEL REPAIR PAGES

IECO 210 HP 4 CYL / POUSTUSA CHEVY VEGA PAGE

RADIO SERVICE RADIO CONVERSION AND MORE

SALVAGE YARD LINKS STATE BY STATE LISTINGS

CLICK HERE FOR EQUIPMENT AND SMALL ENGINE PAGES WITH LINKS HONDA PAGES TOO AND HOW TO!!

CLICK HERE FOR THE MOUSE TRAP PAGES A TRAP THAT WORKS FOR US!!

CLICK BELOW FOR THE COOL UNIT CONVERTER SITE

CLICK HERE FOR SHOP TOOLS AND EQUIPMENT PAGES

CLICK HERE FOR MUST HAVE TOOLS LIST PAGE

CLICK HERE FOR AIRCON SOFT START PAGES

CLICK HERE FOR THE INVERTER WINDOW AC UNITS

CLICK HERE FOR THE ELECTRICAL TOOLS AND PARTS PAGES AND MORE!

NEW CLICK HERE FOR RESTAURANT PAGES

NEW CLICK HERE FOR TRUCK CRAIN BED LIFTS

CLICK HERE FOR THE POWER WASHER PAGES

CLICK HERE FOR THE DRAINZIT OIL DRAIN PAGES

CLICK HERE FOR THE DC FUSE PAGE ATO, ATC, MAXI, GMA

Note:

Spacers not normally recommended.

Note:

Spacers not normally recommended.

,

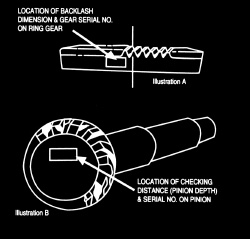

which means a backlash figure of .008 inch at the closest point.

Pinion depth settings (or checking distance) are marked on the face of the

pinion gear as follows (see illustration B): Ref: CD 2.799,

,

which means a backlash figure of .008 inch at the closest point.

Pinion depth settings (or checking distance) are marked on the face of the

pinion gear as follows (see illustration B): Ref: CD 2.799,

which means distance of 2.799 inches from centerline of the ring gear to pinion face. Dimensional variations for backlash SHOULD NOT EXCEED .004" variation.

Properly designed, manufactured, and maintained Richmond Gears, correctly assembled by you in a clean, rigid gear box, and operated with the proper lubricant, should result in safe and satisfactory performance. Be sure you select the proper application for your gear set.

A new ring and pinion installation, especially a high numeric ratio with new bearings, can cause an excessive heat buildup in the rear end and cause softening of the gear teeth and bearings if a break in is not performed.

Street vehicles should be driven at normal street driving speed for approximately 10 miles, then stop and let cool for 30 minutes. Do this 2 to 3 times. Towing vehicles need approximately 200-300 miles of normal street driving before being used for towing.

On circle track race cars make approximately 6 to 8 laps at slow speed, then let cool for 30 minutes. Make 6 to 8 more laps at slow speed, then 2 to 3 laps at full speed, the let cool again for 30 minutes.

Drag cars need only an initial run-in since they are driven short distances and heat is not normally a problem with proper lube and backlash allowance.

NOTE: If after the above break in is performed, overheating of the rear end is suspected, repeat the final portion of the break in procedures.

HELPFUL HINTS & ADDITIONS TO RICHMOND GEAR INSTALLATION INSTRUCTIONS

After completely reading instructions, go back to Step #4. The following group

of shim thickness are only if you do not have access to a pinion depth gauge or

the old shim from the old pinion to start with. GM - .035", Ford 8"-9" - .020",

Ford 8.8"-7.5" - .030", All Dana's - .035", 8 3/4" x 1 3/4" pin, - .090", 8 3/4"

x 1 7/8" pin, - .020", Mopar - 9 1/4" - .020"

Pinion depth shims are located underneath the rear pinion bearing cone that is

pressed on pinion with exception of the Dana Models. Dana pinion depth shims are

underneath the rear pinion bearing cup in the housing. Dana carrier bearing

pre-load shims are between carrier and bearing cone. All others are on the

outside of bearing cup unless spanners are used as in the Ford 8 and 9 inch,

both 8 3/4 and Mopar 9 1/4. Ford 8 and 9 inch pinion depth is regulated by shims

between pinion support and chuck or center section.

Step #5 - If crush collar is used to set bearing

pre-load, do not use until you have established pinion depth and backlash and

you are satisfied with the pattern you get. You can simulate pinion bearing

pre-load by tightening pinion nut until the right pre-load is achieved with only

motor oil on the pinion bearings. The crush collar and pinion seal should be

last to install.

Step #7 - GM rear cover style housings use shims on

the outside, between bearing cup and housing, adjusting backlash and carrier

bearing pre-load If starting with a bare housing, or you are installing a spool

or different carrier, before you mount the ring gear, establish equal shim pack

on each side of carrier and enough to create a drag when you slide it in and out

of the housing by hand. Keep in mind you should keep the thickest shim next to

the bearing cup. With a little loctite on the threads of the rings gear bolt,

mount gear to carrier or spool. After adjusting shim pack to get proper backlash

and once you have established your pattern, remove carrier and pinion. Now is

the time to install crush collar and pinion seal. NOTE" Always use loctite on

the pinion nut. If you do not have a rear end housing spreader, you will have to

work at installing the carrier once you add more shim to pre-load the carrier

bearings. As a rule of thumb all carrier bearings will require .010 pre-load

After adding .005 to each side of the shim pack, coat surfaces of the shims with

axle bearing grease to hold them in the housing, make sure the cups stay

straight. Using a plastic or brass hammer, gently pound on bearing cups side to

side until carrier has seated in housing. Again, it is important that you keep

the cups straight during this operation. A spreader is almost necessary for all

Dana Model rear ends. Torque caps to proper torque value.

LOGO'S

![[Most Recent Quotes from www.kitco.com]](http://kitconet.com/images/quotes_7a.gif)